Trouble-free Offshore Manufacturing. Really?

Trouble-free Offshore Manufacturing. Really?

Adding 10%, 20% or 30% to your bottom line margin is a pretty big motivator to consider manufacturing in Asia. However, based on scary Internet posts, or your entrepreneur friend’s failed attempt ordering product offshore through a gigantic Web portal, you might be wondering if it’s possible to engage in manufacturing overseas without major complications.

Here are five keys to help you take advantage of trouble-free offshore manufacturing in China.

Key #1: Chinese Holidays Matter

China has distinct advantages over outsourcing your manufacturing to other Asian markets, mostly because they have a longer history of maintaining the higher standards set by their Western business partners.

So why are Chinese National Holidays such a big factor to emphasize?

In the West, texting under the Thanksgiving dinner table, or slipping away to confirm a looming January product delivery while the kids open their Christmas presents is no longer a big deal. You may have done this yourself.

In China, everyone from chief executives to factory line workers, closely observe all national holidays. Work and business communication cease almost completely to allow for travel and focus on family. According to China’s National Development & Reform Commission, approximately 3.6 billion trips were made during the 40-day period surrounding the Spring Festival 2014, making it the largest human migration in the world.

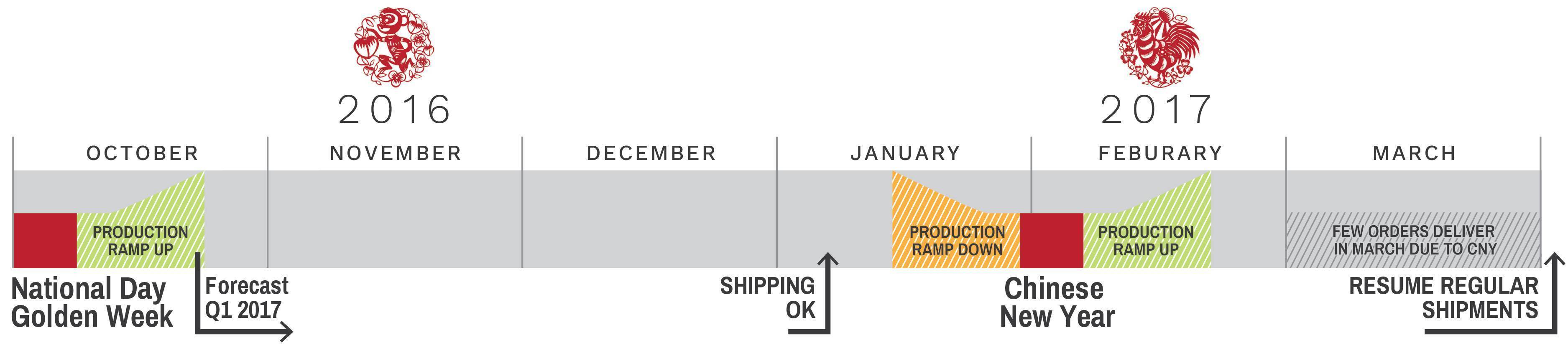

The two main “Golden Weeks” celebrations likely to impact your production are Chinese New Year (CNY), which takes place in January or February, and the National Day Golden Week that occurs near the beginning of October.

Workers receive three days of paid holidays plus the adjacent weekends to give them a full seven days of time off. One to two weeks before each celebration, all suppliers start to wind down operations in advance; no new orders accepted; mass production and sample development are halted. As the migration returns, getting operations back up to full speed takes time, creating trickle-down disruptions across supply chains depending on the industry.

Ignoring these important cultural differences and timeframes can cost you valuable go-to-market time. In fact, not planning around them could bump product development or shipments into the following calendar year buying cycle in the West.

To help negate any issues, one of the best things you can do is establish a strong relationship with your manufacturing partner or supplier early on. Develop your schedules for lead times, tradeshow samples, shipping, and product rollouts accounting for potential productivity gaps stemming from the major Chinese holidays. Once you reverse engineer key dates from your desired product ship dates it’s easy to reduce potential interruptions.

Here is a sample CNY schedule to help you plan. (Apply the same time spread for National Day Golden Week in October.):

Key #2: A napkin sketch won’t do.

Good design is key to any successful product. It’s especially important when those design details need to be executed by people which are continents, cultures, and languages away.

To preserve your design integrity, it’s best to develop your own innovation and brand aesthetic as far down the pathway as possible before handing it off to an offshore manufacturer.

Put simply, you need to be crystal clear about your product expectations.

For you, that may mean delivering computer-assisted design (CAD) drawings complete with Bill Of Materials (BOM).

Others may need more research understanding compliance or regulatory requirements for an electronic, toy, or FDA controlled product before engaging in product development.

If you’re at the concept, sketch-only stage, steer clear of online sourcing or manufacturing brokers. Instead, research a manufacturer that has full-service product development capability in-house, or one that offers a manufacture readiness program. They can walk you through all the steps required to create a viable prototype. (Or, get your prototype built stateside first.)

Spend the time up front to ensure your product is ready for manufacturing. The extra effort refining the specifics of your design early will save you time and money down road — and aid in your search for a prospective manufacturing partner. Then you can move forward with the least amount of risk to successfully build your vision.

Key #3: Look beyond price.

It’s no secret when it comes to offshore manufacturing, Alibaba Express probably comes to mind first. In the U.S. there are maybe half a dozen factory choices (or even less) for your product, with upfront capital requirements as the main selection criteria. In Asia, there will likely be dozens of possible factories to choose from, each differentiated by size, production capability, experience, and more.

This means you will be able to find multiple factories that could produce your product. However, this multitude of choices also raises the obvious question: Which one will be the perfect fit?

The key is to look beyond basic production capability to find a factory and team with the following attributes:

- expresses an understanding of your brand goals and design direction (Key #2)

- prior related experience with products like yours

- workable minimums

- quality standards and accountability you are looking for

Don’t leave the all-important choice of the right factory for your product to a broker who bids out projects on the basis of cost alone. Do your homework. Find the manufacturer that fits both your product and your business.

Key #4: “Quality” doesn’t always translate

“Made As China” declared the men’s dress shirt tag hanging in a Shanghai market. Funny Engrish; sure. Symptomatic; absolutely.

While manufacturing standards have dramatically increased in China over the past decade, attention to quality manufacturing from West to East can still be drastically different. Some things just get lost in translation.

The root cause of most failed offshore production stories stem from the inability to get your exact product requirements and quality control specifications met.

Obviously, many factors influence cross-cultural business communication. The good news is that a conscientious Chinese manufacturing partner wants a strong and successful relationship as much as you do.

Here are three things you can do to make it easy for your manufacturing counterpart to serve you with excellence:

- When it comes to executing your design, a picture is worth more than words. Sketches (with design direction notes) and CAD drawings are a proven form of cross-cultural communication in the manufacturing world. Supplying 3D models and/or illustrations can help take design clarity one step further.

- Document all communication digitally. Make it easy for the entire team to review spec-sheets, critical calendar dates, and contract details in real time, either online or offline for later follow-up.

- Use video-calling when needed. Body language and facial expressions are a huge help in confirming how well information is being shared and received.

Three things you can do to protect your product integrity in the development process:

- Look for manufacturing or supply chain resources with a bona fide Chinese manufacturer business license.

- Ask if they are willing to supply manufacturing audit and supplier evaluation, or a factory audit report.

- Ask for a pre-production sample and test the product prototype yourself before the full production run.

Key #5: Protect your Ideas

“Fences make for friendly neighbors,” is the American expression implying the importance of well-communicated boundaries. When it comes to companies manufacturing in China, Intellectual property (IP) protection continues to be “friendly neighbor” concern.

IP protection is also one of the top priorities of the US-China Business Council (USCBC). Obviously, the topic is deeply involved and the USCBC best practices document lays out key strategies and tactics companies can adopt to identify and protect their IP in China.

The first line of IP defense is the integrity of your offshore manufacturing partner. Be clear about your business ethic expectations upfront. Depending on your product complexity and budget, a visit to the factory is a great way to build trust and a successful long-term, cross-cultural working relationship.

In the end, remember Business 101. Your highest level of protection comes from continually innovating and staying ahead of your competition.

Rewards with Some Risks

Clearly, there are many factors to research, but the benefits of offshore manufacturing make it an option worthy of consideration.

Manufacturing in China offers the positives of turnkey production, lower costs, realistic minimums, and gives you plenty of options. Today, working with the right manufacturing partner, you can actually achieve more complex and creative product in China compared to many operations in the U.S.

You can save a frustrating experience with the right help. Work through these five key factors. Focus on what you know best — your product and market. Get it ready to go. If it makes sense, reach out to a qualified manufacturing partner in Asia to help you make your product a reality.

![]()

Product Crew is an American owned and operated custom manufacturing company with offices in the U.S., Hong Kong, and China. With 25 years of manufacturing experience in Asia, the parent company, Custom Manufacturing Solutions, was one of the first 100 U.S. companies internationally certified and registered to operate in China.

Unlike many overseas manufacturers, Product Crew is vertically integrated, managing the entire supply chain: product design, development, engineering, QA/QC, production line management, packaging, freight, logistics,import, customs, and more. This strategic position allows the company to deliver a superior product, at competitive pricing, faster.

If you’re interested in production support on-the- ground in Asia, custom manufacturing, or a trustworthy supplier, contact Product Crew.